Uchungechunge submersible indle futha WQ

Iphampu yemfucumfucu iwuhlobo lomkhiqizo wepompo oxhunywe nenjini futhi usebenza ngaphansi koketshezi ngasikhathi sinye.Uma kuqhathaniswa nephampu evamile evundlile noma iphampu yokuthuthwa kwendle eqondile, iphampu yokukhucululwa kwendle ihlangene ngesakhiwo futhi ithatha indawo encane.Ukufakwa nokugcinwa kulula.Amaphampu amakhulu okukhuculula indle ngokuvamile anezisetshenziswa zokuhlanganisa ezizenzakalelayo ukuze zifakwe ngokuzenzakalelayo, ezilungele ukufakwa nokugcinwa kwazo.Isikhathi eside sokusebenza esiqhubekayo.Njengoba iphampu ne-motor ku-coaxial, i-shaft yepompo yokuthuthwa kwendle ifushane, futhi isisindo sezingxenye ezijikelezayo silula, umthwalo (radial) ekuthwaleni kuncane kakhulu, futhi impilo yesevisi yepompo yokuthuthwa kwendle yinde kakhulu. kunaleyo yephampu evamile.Awukho umonakalo we-cavitation, izinkinga zokuchelela kanye ne-diversion.Ikakhulukazi, iphuzu lokugcina liletha ukunethezeka okukhulu kubaqhubi.Umsindo wokudlidliza ophansi, izinga lokushisa eliphansi lemoto, akukho ukungcoliswa kwemvelo.

Sicela unake ukuhlela nokusakaza

1. Qiniseka ukuthi indawo yokusebenza yephampu yamanzi ehlanzekile, bese ukhetha uhlobo lwepompo olulungile (ngokuvamile uhlobo olumanzi kanye nohlobo olomile)

2. Bala ukuphakama okudingekayo kwepompo.Kwesinye isikhathi, amakhasimende abala ibanga eliyisicaba lokudlulisa ekhanda, okungalungile.Ikhanda lingabalwa kuphela ngemva kokuba ibanga eliyisicaba lokudlulisa liphindaphindwe nge-coefficient yokungqubuzana.

3. Ukugqoka indololwane yepayipi kanye nokungqubuzana kwamapayipi kufanele kufakwe, okuhlukile ezimweni zangempela, futhi kubuye kube nzima ukubala ngokunembile, ngakho-ke kunconywa ukushiya indawo ethile ukuze kuqinisekiswe ukuthi iphampu yamanzi ingakwazi ukupompa amanzi.

4. Uma ipompo yokukhucululwa kwendle yensimbi engagqwali ikhethiwe, i-pH yekhwalithi yamanzi, kuhlanganise nobubanzi bezinhlayiyana, kufanele futhi icaciswe, futhi kukhethwe izinto ezifanele zensimbi engagqwali.Ngokuvamile, izinto ezingu-304 zifanele i-PH4~10.Kunconywa ukusebenzisa insimbi engagqwali engu-316 noma engu-316L ngale kwalolu bubanzi.

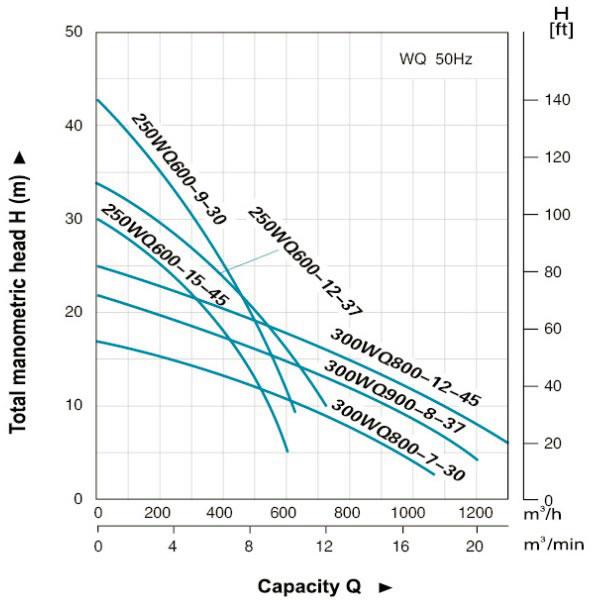

5. Iphampu yamanzi kufanele isetshenziswe ngaphakathi kwebanga elilinganiselwe lokuphakamisa ukuze kuqinisekiswe ukuthi injini ayilayishiwe ngokweqile.

Isibonelo, i-lift edingekayo yangempela ingamamitha angu-30, kodwa ukusebenzisa iphampu enokuphakama okujwayelekile okungaphansi kwamamitha angu-30 ukumpompa amanzi kuyindlela yokusebenzisa okungalungile, okuzobangela ukugcwala kwenjini.Ezimweni ezimbi kakhulu, injini izoshiswa.

6. Ipayipi lephampu lamanzi kufanele livulwe.Uma ipayipi livaliwe, injini izophinde ilayishwe ngokweqile, futhi ezimweni ezimbi kakhulu, injini izoshiswa.

Ububanzi bokusetshenziswa

① Ukukhishwa kwamanzi angcolile kwamabhizinisi.

② Uhlelo lokulahla isizinda sokukhuculula indle emadolobheni.

③ I-Metro, indawo engaphansi, isiteshi sokudonsa amanzi sohlelo lokuvikela umoya womphakathi.

④ Ukukhishwa kwendle ezibhedlela, amahhotela nezakhiwo eziphakeme.

⑤ Isiteshi sokuhambisa indle endaweni yokuhlala.

⑥ Ukukhishwa kodaka emisebenzini kamasipala nasezindaweni zokwakha.

⑦ Ithuluzi lokuphakela amanzi lemishini yamanzi.

⑧ Ukukhishwa kwendle emapulazini afuywayo kanye nokuchelelwa kwezindawo zasemakhaya.

⑨ Ukusekela izimayini zokuhlola kanye nempahla yokuhlanza amanzi.

⑩ Esikhundleni sokuthwala abantu emahlombe abo, bancela futhi bathumele udaka lomfula.

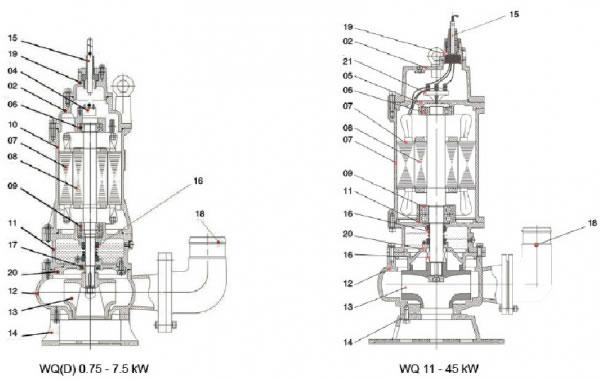

| Cha. | Ingxenye | Okubalulekile |

| 1 | Bamba | Insimbi |

| 2 | Ikhava Engaphezulu | Insimbi |

| 3 | I-Capacitor | |

| 4 | Umvikeli oshisayo | |

| 5 | Isihlalo Sokuthwala Esingaphezulu | 304/316/316L |

| 6 | I-Bering | |

| 7 | Stator | |

| 8 | Irotha | |

| 9 | Ukuzala | |

| 10 | Umzimba Wezimoto | 304/316/316L |

| 11 | Ukuthwala Isihlalo | 304/316/316L |

| 12 | Umzimba Wepompo | 304/316/316L |

| 13 | Impeller | 304/316/316L |

| 14 | Isisekelo | 304/316/316L |

| 15 | Ikhebula | |

| 16 | Mechanical Seal | I-Sic-Sic/Carbon-Ceramic(< 7.5kw) i-Sic-Sic/Sic-Sic(>7.5kw) |

| 17 | I-Oil Seal | |

| 18 | I-Hose Coupling | 304/316/316L |

| 19 | Ibhokisi leTheminali | 304/316/316L |

| 20 | I-Seal Bracket | 304/316/316L |

| 21 | I-Wiring Terminal |